The Ultimate Guide to PLC Board Repair and Electronic Components Distribution in Canada

In today's fast-paced technological landscape, businesses rely heavily on sophisticated machinery and automation systems. Central to these systems are Programmable Logic Controllers (PLCs), which play a crucial role in modern industrial processes. However, like any electronic device, PLCs can experience failures, which often necessitates professional PLC board repair. In this comprehensive guide, we will explore everything you need to know about PLC board repair services and electronic components distribution in Canada, specifically focusing on how reputable companies like QF Automation can enhance your operational capabilities.

Understanding PLCs and Their Importance in Automation

PLCs are robust digital computers used for automation of electromechanical processes, such as controlling machinery on factory assembly lines, amusement rides, or light fixtures. They are favored in industrial applications due to their:

- Durability: Designed to withstand harsh conditions, including extreme temperatures, humidity, and electrical noise.

- Flexibility: Can be easily programmed and reprogrammed for different tasks.

- Scalability: Capable of controlling an increasing number of inputs and outputs as the operation expands.

The reliability of PLCs is essential; a failure can halt operations, leading to significant financial losses. Therefore, understanding the necessity of PLC board repair is imperative for businesses relying on these devices.

Common PLC Issues That Require Board Repair

Several factors can contribute to a malfunctioning PLC board. Below are some common issues:

- Electrical Failures: Power surges or short circuits can damage components on the PLC board.

- Environmental Factors: Dust, moisture, and temperature fluctuations may lead to failure in PLC operations.

- Component Aging: Over time, even the best components degrade, leading to functional failures.

- Software Glitches: While the hardware may be intact, improper software can prevent PLCs from executing commands accurately.

Identifying these issues promptly allows businesses to avoid prolonged downtimes and disruptions.

The PLC Board Repair Process

The PLC board repair process typically involves several crucial steps:

1. Diagnosis

The first step is to identify the root cause of the failure. Experienced technicians use diagnostic tools to assess the condition of the PLC board and its components. This step is vital to ensure accurate repairs.

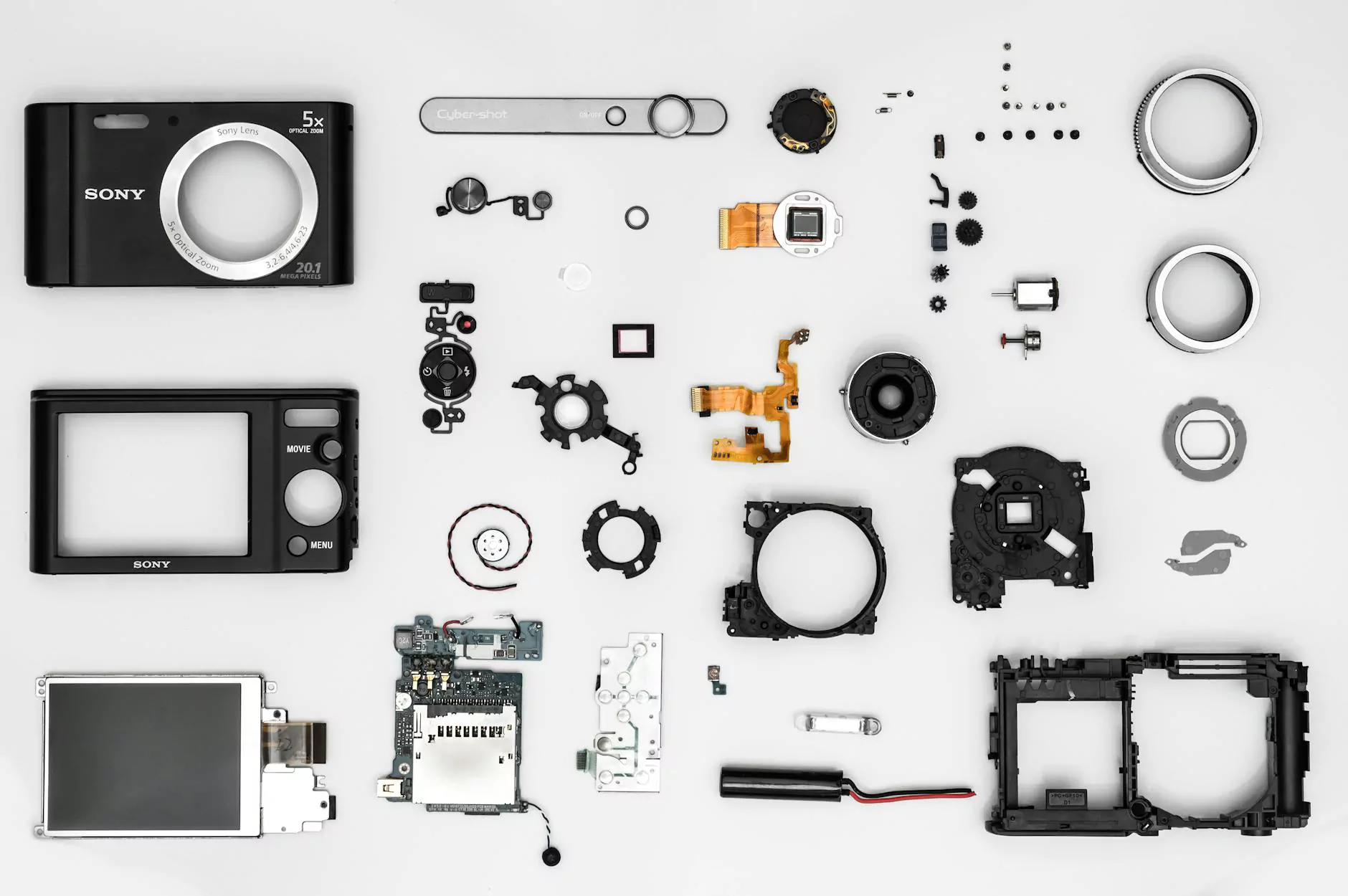

2. Disassembly

Once diagnosed, the PLC board is carefully disassembled, allowing access to internal components for inspection and testing.

3. Repair or Replacement

Based on the diagnosis, technicians can either repair the damaged components by replacing resistors, capacitors, or chips, or opt for full board replacement if the damage is extensive.

4. Testing

After repairs are made, the board undergoes rigorous testing to ensure all functionalities are restored. This step is crucial for verifying the reliability of the repair.

5. Reassembly and Quality Check

The final step involves reassembling the PLC board and conducting a quality check to ensure it meets performance standards before returning it to the customer.

Why Choose Professional PLC Board Repair Services?

While some businesses may consider in-house repairs, engaging professional PLC board repair services offers immense advantages:

- Expertise: Trained technicians possess the necessary knowledge and experience to handle various types of PLCs.

- Time Efficiency: Professionals can expedite repairs, minimizing downtime for your operations.

- Cost-Effectiveness: Investing in professional services can save money in the long-term by preventing further damage and ensuring accurate repairs.

- Guaranteed Work: Many service providers offer warranties on repairs, providing peace of mind for businesses.

The Role of Electronic Components Distributors in Canada

In conjunction with maintenance and repair services, having a reliable supplier for electronic components is crucial for any business involved in automation. Canada boasts an array of reputable electronic components distributors, including QF Automation, providing:

1. Extensive Product Range

From PLCs to sensors and relays, leading distributors stock a wide variety of products catering to diverse industrial needs.

2. Quality Assurance

Reputable distributors prioritize quality, sourcing components from trusted manufacturers to ensure their products meet rigorous standards.

3. Technical Support

Many distributors provide specialized support and guidance, assisting businesses in selecting the right components for their unique applications.

4. Timely Delivery

With a robust logistics network, top distributors can guarantee prompt delivery, minimizing the wait times for critical components.

Integrating PLC Repair with Your Supply Chain

To maintain consistent operational flow, integration of PLC board repair services with your component supply chain is vital. This strategy includes:

- Regular Maintenance Checks: Schedule routine evaluations of your PLC systems to identify potential issues before they escalate.

- Establishment of Vendor Relationships: Build strong ties with trusted suppliers and repair services for seamless communication and cooperation during emergencies.

- Inventory Management: Keep a well-stocked inventory of essential components to reduce wait times for replacements and repairs.

- Staff Training: Equip your personnel with the knowledge to perform basic diagnostics one setting the groundwork for effective maintenance practices.

Conclusion: Ensuring Business Continuity through Expert Services

In conclusion, understanding the critical role of PLC board repair and the importance of reliable electronic components distribution is essential for modern businesses that hinge on automation. By choosing to work with established providers like QF Automation, companies can ensure that their PLCs function optimally, minimizing downtime and enhancing productivity. Prioritizing professional repair services and establishing solid supply chain management will ultimately safeguard your business against unforeseen technical hiccups, allowing you to focus on innovation and growth.

Take Action: Reach Out for Expert PLC Board Repair Services

Don’t let equipment failures disrupt your operations. Contact QF Automation today to learn more about our expert PLC board repair services and discover how we can help your business run smoothly and efficiently.